After plasma surface treatment reaches a higher surface, immediately proceed to the next process to avoid the impact of surface energy attenuation. The surface modification of the plasma surface treatment machine is an effective way to control the surface, and the energy and chemical properties of the substrate do not affect the bulk materials.

Full Answer

What does plasma do to a surface to improve adhesion?

There are a few methods to do this:

- Use a mixture of 50/50 isopropyl alcohol (IPA)/water. This is generally adequate for plastics which don’t require oily coatings to protect their integrity.

- Clean with harsher solvents, including acetone or methyl-ethyl ketone (MEK). ...

- Degrease with an industrial degreaser, followed by solvent cleaning. ...

What equipment is used for plasma?

Why ReportsnReports.com?

- 500,000 market research reports and growing.

- Top Fortune 500 Organizations trust us for research data.

- 24/7 support on call as well as emails.

- Your Details are safe with us.

- Free support for your research requirements.

- Report Delivery: Email

- Delivery Time: Upto 24 hrs - working days Upto 48 hrs max - weekends and public holidays

What is surface treatment process?

Types of Conversion Coatings

- Coating with Oxides. Coatings done by the help of oxides are actually corrosion products that include an oxide with negligible thickness leading to good adhesion.

- Chromate Coating. These coatings involve the process of chemical conversion formed by a reaction occurring between chromium salts or chromic acid water solutions.

- Phosphate Coating

What can plasma treat?

Surfaces of polyolefins are treated by plasma to change a surface to hydrophilic by oxidation. Other known results of plasma treatment include dehydrogenation, the formation of radicals, and roughening of the surface.34 Figure 10.2 shows the effect of plasma treatment duration on a specific surface area of acrylic fibers.

How does plasma surface treatment work?

What is Plasma Treatment? Plasma treatments are used to alter the surface properties of a wide range of materials to make them easier to bond, glue and paint. By treating parts we both clean and activate the surface, improving their adhesion characteristics.

What is plasma treatment surface modification?

Plasma treatment is a surface modification technique that readily primes any surface for better acceptance of secondary manufacturing applications. Plasma is a reactive treatment process where positive and negative ions, electrons, and radicals react and collide as long as an electric potential difference exists.

How long does plasma surface treatment last?

approximately 48 hoursMost plasma treatments last approximately 48 hours if the treated surface remains clean and dry. This time can vary depending on the treatment performed and the conditions parts are stored in.

What is the advantage of plasma surface treatment?

Plasma surface treatments show distinct advantages, because they are able to modify the surface properties of inert materials, sometimes with environment friendly devices. For fabrics, cold plasma treatments require the development of reliable and large systems.

What is plasma technique?

Plasma technology has been in use for the synthesis, processing, treatment, and deposition of polymers, nano-particle or nano-porous structures, textile surfaces, and etching, etc. Moreover, it is a clean and eco-friendly technique which minimizes waste, unlike wet-chemical processes.

What is plasma treatment in printing?

Plasma Treatment in Inkjet & Print Industry The UV ink, which is used to spray the QR code, has poor adhesion and must be treated with plasma to ensure that this material does not fall off.

What do you put on skin after plasma pen?

Apply a fine layer of Vaseline ointment (or topical advised by your doctor) to treated areas several times a day if needed to maintain continuous layer on skin for the first 2 days. Be sure to thoroughly wash your hands prior to touching your face.

How often is plasma treatment?

For optimal results, a further treatment every 4-6 weeks is recommended for a total of 3 treatments. We recommend regular maintenance at yearly intervals for sustained results.

How often can you do plasma pen?

Any additional treatments that may be required must only be performed once the skin is completely healed and has returned back to its normal color. This usually takes about 12 weeks.

What are the disadvantages of plasma?

Disadvantages of plasma display :Commonly do not come in smaller sizes than 40 inches.Heavier in weight with respect to screen size.A picture is not so clear under bright conditions.Glass screen damage can be permanent and far more difficult to repair.Poor reproduction of black.Radiation is emitted for screen.More items...

What is plasma pre treatment?

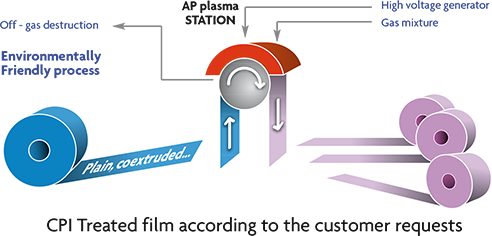

Atmospheric pressure plasma pretreatment is one of the most efficient processes for cleaning, activating or coating materials such as plastic, metal (e.g. aluminium) or glass. Fine cleaning and plasma activation with atmospheric pressure plasma is highly efficient.

What is air plasma treatment?

A plasma treatment is usually performed in a chamber or enclosure that's evacuated (Vacuum plasma). The air within the chamber or enclosure is pumped out prior to letting gas in. The gas then flows in the enclosure at a low pressure. This is done before any energy (electrical power) is applied.

What is plasma?

Plasma is one of the four fundamental states of matter. While the states solid, liquid and gas are well-known to all of us because they are part of...

What is plasma treatment used for?

Plasma treatment is used to modify the surface of an object. Many solid materials have a low surface energy, which results in a poor wettability an...

What are the main effects of Plasma treatment?

The major effects of a Plasma treatment are: 1. Surface cleaning: Treatment with plasma removes any foreign contaminants present on the surface of...

How does plasma treatment work?

Plasma consists of electrons, molecules or neutral gas atoms, positive ions, UV light along with excited gas molecules and atoms and carries a high...

Can I treat heat sensitive parts with plasma?

Plasma treatments performed at low temperatures can easily process materials that are heat sensitive. These types of plasma are sometimes referred...

How long does a plasma treatment take?

Treatment cycle times are often short, between 2-120 seconds depending on the treatment technology, the treated material and size of the part.

How long do the effects of a plasma treatment last?

The lifetime of a plasma treatment can last from hours to years depending on the material and the applied treatment as well as the subsequent stora...

How good do plasma treated parts bond?

The enhancement can range from a 2-fold to a 10-fold improvement in lap-shear strength and peel- strength compared to untreated parts.

Which materials can benefit from Plasma treatment?

Nearly all materials can benefit from plasma treatment. Plastic and rubber materials are the most common materials that challenge our customers wit...

Is plasma treatment eco-friendly?

Plasma treatments are a lot more environmentally friendly than traditional surface treatment methods, which often rely on the use of high temperatu...

What is plasma treatment?

Plasma treatment generally is a term generally applied to vacuum plasma treatment although technically flame, corona, and atmospheric plasma [15–31] are also plasma treatments. Each of these plasma types has different characteristics and may have different treatment depths as well as resulting in a different final surface chemistry.

Why do acrylic fibers need plasma treatment?

Plasma treatment causes better surface wettability because of formation of carboxyl and amide groups on the fibers’ surface, which increases hydrophilic properties of the surface.

What is plasma wool?

Plasma treatments of wool represent a most innovative approach to replacing chlorination stages in wool finish ing and to improving existing processes with special regards to an economical–ecological optimisation. The apparent potential of plasma technology for wool finishing processes led to the development of machinery allowing a treatment under atmospheric conditions for different fibre make-ups. This can be regarded as a large step towards industrial implementation that will help the wool industry to benefit in the near future from a technology that is extremely surface-specific, totally effluent free, and thus less destructive and more environmentally friendly. The implementation of plasma technology into the wool industry is closely connected to further developments towards larger-scaled machinery, allowing a cost-efficient treatment with special regards to a high material throughput, as well as to the development of highly efficient tailored auxiliaries for achieving special effects.

Why is plasma used in polyolefins?

10.5 PLASMA TREATMENT. Plasma treatment found primary use in polyolefins because of their inertness and lack of adhesion. Surfaces of polyolefins are treated by plasma to change a surface to hydrophilic by oxidation.

Is atmospheric plasma treatment more expensive?

This has meant that the use of atmospheric plasma treatment sources is increasing. The atmospheric plasma treatment tends to be a higher cost process as the power supply is more expensive and the consumption of helium also presents a higher running cost.

Is plasma treatment safe?

Plasma treatments are environmentally safe as they do not release toxic organic solvents and are easy to control; current, pressure and voltage being the main parameters. Moreover it is reproducible. However, in spite of this, plasma-aided technology is not considered as a viable one mainly because of the complexity of the processes involved during the plasma treatment [22] and ageing of the polymer after treatment. Different strategies have been explored for improving the wettability of polymers, and plasma treatment has a major role among others. Atomic Force Microscopy has emerged as a valuable tool providing insight into the structure and properties of polymers. Plasma treatments lead to the formation of radicals that promotes surface crosslinking or functionalization thereby improving the surface properties [23]. A comparison of surface modifications of carbon fiber using various techniques is presented by Sharma et al. [24]. The atomic force microscopic images ( Fig. 11.10) show the effect of the various surface modification techniques on the surface of the carbon fibers.

Is PVDF smoother than PET?

The PET surfaces are mostly smooth and the PVDF surfaces are much rougher. However, where the PET surface became smoother after plasma treatment, the PVDF maintained nearly the same roughness on the 30 mm scale. On the 0.5 or 1 mm scale, the surfaces of both polymers show common bump-like features.

How to optimise agitators

Sulphuric acid is the key chemical used in the production process of wet phosphoric acid. …

Easier design integration and faster supply: the development of the standard parts industry

Standard parts and components are as vital to engineering today as they were in the …

Ultra-precise stainless steel processing

Jochen Kern discusses the use of stainless steel with photochemical etching and looks at the …

What happens when plasma bonds with a material?

When Plasma bonds with a material it enhances the material energy or wettability, enabling it to bond easier as part of the Plasma Surface Treatment process. When the plasma bonds with a material, the transferred energy allows chemical reactions ...

Is plasma more durable than PTFE?

Plasma is more robust than PTFE and is more sustainable as it doesn’t consume or waste any materials. The process of Plasma Surface Treatments is much more sanitary than PTFE coatings. PTFE is an adhesion of Teflon powder which, if not well processed, can release residue and impact the sterility of equipment and machinery.

Is plasma surface treatment cheaper than PTFE?

Plasma Surface Treatment is also inexpensive when compared to PTFE, and provides more consistency in terms of performance than that of Chlorination.

Most recent answer

Thank you to all for your replies and the attached files. I realized I have to cook and look for my results and hopefully not thinking in the direction of active and reactive plasma power.

Similar questions and discussions

Atmospheric pressure gas jet simulation with COMSOL, how to view the gas concentration distribution inside and outside the tube at the same time?