With rounded openings of 0.010 to 0.5 inches, these screens are typically found in small wastewater treatment plants. Rotary drum screens. This screen is placed on a rotating cylinder in the flow channel, and it traps solids on its surface. As the screen spins, a collective of cleaning brushes or water spray cleans debris off the drum.

Full Answer

What type of screen is used in a wastewater treatment plant?

Nov 04, 2021 · Manually cleaned screens. This screen is generally mounted at a vertical angle, between 30 to 45 degrees. It has a spacing of 1 to 2 inches between its bars. The bars capture screenings when...

What is the importance of screening in wastewater treatment?

Coarse screens remove rags, sticks, large solids and other debris ranging from 0.25 to 6 inches. They can be as simple as a trash rack or as complicated as a mechanically cleaned bar screen.

What are the different types of fine screening in wastewater treatment?

Dec 17, 2017 · Reciprocating rake (Climber screen): In this type of screen the rake moves to the base of the screen, engages the bars and pulls the screenings in to the top of the screen where they removed. This screen uses only one rake instead of multiple rakes that are used in …

How is waste water treated in a water treatment plant?

Mar 20, 2018 · Used in the screening process in wastewater treatment at small facilities, hand cleaned coarse screens are hand raked. They are ideal to use as a standby during periods of high flow, or when more modern mechanical screening methods are under repair or maintenance. Mechanically cleaned screens

What are the 4 main steps of cleaning water at a wastewater treatment plant?

Water treatment stepsCoagulation. Coagulation is often the first step in water treatment. ... Flocculation. Flocculation follows the coagulation step. ... Sedimentation. Sedimentation is one of the steps water treatment plants use to separate out solids from the water. ... Filtration. ... Disinfection.

What is screen in wastewater treatment?

Screening is the first unit operation used at wastewater treatment plants (WWTPs). Screening removes objects such as rags, paper, plastics, and metals to prevent damage and clogging of downstream equipment, piping, and appurtenances. Some modern wastewater treatment plants use both coarse screens and fine screens.

How many types of screens are present in wastewater treatment?

Typically, there are four types of screening media used, which are bars, wedge wire, perforated plate, and mesh as shown in Figure 2. Bar screen media is the most commonly used, especially for coarse screens and trash racks. The shapes of bars include rounded, rectangular, trapezoidal, and teardrop.

How does a bar screen work?

Bar screens generally operate in a conveyor-like system. Solids are picked up by a bar or wire filter that allows the water through. The filter is either intermittently or continuously moved through and out of the water channel to a motorized cleaning and trash area.

What is the role of bar screens in wastewater treatment plant?

A bar screen is a mechanical filter used to remove large objects, such as rags and plastics, from wastewater. It is part of the primary filtration flow and typically is the first, or preliminary, level of filtration, being installed at the influent to a wastewater treatment plant.

What is screening and straining in water treatment?

Screens or sieves are great for straining larger particles out of water and are a simple, but flexible technology for diverse configurations. These work well applied at (inlet of) central treatment facilities, but simple use makes it suitable for decentralized or rural applications.Nov 17, 2016

Why are screens necessary before the treatment of wastewater?

Screening is a wastewater pre-treatment, which aims to prevent coarse solids, such as plastics, rags and other trash, from entering a sewage system or treatment plant. Solids get trapped by inclined screens or bar racks.

What materials Cannot be removed from wastewater?

When wastewater arrives at the treatment plant, it contains many solids that cannot be removed by the wastewater treatment process. This can include rags, paper, wood, food particles, egg shells, plastic, and even toys and money.

What is the opening of fine screens?

0.25 in.What is the opening of fine screens? Explanation: Fine screens have openings of less than 0.25 in. and are used to remove solids smaller than those retained on bar racks. They are used primarily in water or wastewater containing little or no coarse solids.

How do you clean a bar screen?

The bar screens are cleaned by scrapers and rakes driven by an endless chain system that lifts the waste up the entire bar screen rack and flap and then drops back to a position away from the bar screen rack. A powered waste removal system is often used to clear the top section.

Why is waste water passed through bar screen?

Answer : (1) In a wastewater treatment plant, a bar screen removes large solid objects from the water. (2) The wastewater is allowed to pass through bar screen so that large solid objects such as rags, napkins, sticks, cans, plastic bags, polythene, etc. present in wastewater can be removed.

What is primary clarifier in wastewater treatment?

The primary clarifiers are used to separate settle able solids from the raw incoming wastewater. These are located on the downstream of the plant. The major function of the primary clarifier is the removal of all settle able and floating solid waste which have a high oxygen demand – BOD.

What is the purpose of wastewater screening?

The main purpose of screening is to remove solid materials that could :

What is a fine screen?

They consisted of perforated plates, wire cloth, wedge wire elements that have smaller openings. They are also used to remove the fine solids present in the primary effluent. Fine screens are classified as:

What is a catenary screen?

Catenary screen: They have the rake which is held against the rack by the weight of chain. They are front cleaned, front return chain driven screen. If heavy objects become jammed in between the bars, the rakes will pass over them instead of further jamming in it.

How does a movable screen work?

The fixed and movable step plates alternate across the width of channel and together form a single screen face. The movable plate rotates in a vertical motion. Through this the solids collected on the screen face is lifted up to the next fixed step landing and transported to the top of the screen to discharge into outlet.

What is a bar rack?

So it is also call as “bar rack” and used to remove coarse solids such as rags and large objects that may clog or cause damage to other appurtenances. Based on the Wastewater Screening method used to clean them, coarse screens are classified into two: Hand cleaned screens. Mechanically cleaned screens.

What are the different types of wastewater screening?

There are three broad categories in which you can classify wastewater treatment screens – coarse, fine and micro . Within these categories are many different varieties of screening. The screens are classified based on the size of the screening openings, as well as other mechanical traits.

What is the smallest type of screening?

The smallest type of screening in wastewater treatment is micro screening. These screens are typically low-speed drum screens. The drums are lined with filtering fabrics with openings of 10 to 35µm. Wastewater enters the drum, and the retained solid waste is collected and disposed of.

What are fine screens?

The screening process in water treatment plants employs screens that have clear openings less than 6mm called fine screens. They are made of wire cloth, wedge wire or perforated plates. Like micro screens, they are tools for screening in wastewater treatment that are used to remove fine solids. Three common types of fine screening in wastewater treatment are: 1 Drum Screens (rotating cylinders in the flow channel) 2 Step Screens (fixed and movable plates across the width of the channel) 3 and Static Wedge Wire Screens (used by large treatment plants with ample floor space)

What is a hand raked screen?

Used in the screening process in wastewater treatment at small facilities, hand cleaned coarse screens are hand raked. They are ideal to use as a standby during periods of high flow, or when more modern mechanical screening methods are under repair or maintenance.

What is a bar rack?

It is also called a “bar rack” and used to remove coarse solids such as rags and large objects that may clog or cause damage to other appurtenances. Based on the wastewater screening method used to clean them, coarse screens are classified into two types:

How to clean a water treatment plant?

Among the methods used to clean such plants, dry ice method is the one that makes the clean up faster and less expensive. Waste water treatment plant cleaning includes cleaning of: 1 Filter Presses 2 Clarifiers 3 Tanks 4 Pumps 5 Electric Motors 6 Other Filtration systems

How does waste water get cleaned?

Waste water gets cleaned with the help of huge waste water treatment plants . These plants also need to be cleaned and maintained properly to avoid any kind of pollutants getting dissolved in the clean water. Cleaning waste water is a part of sewage treatment which deals in the cleaning of water especially from household sewage.

Is waste water harmful?

Waste water contains numerous elements and substances that are harmful. These are removed with the use of treatment plants. Now, these plants are to be cleaned, maintained and emptied frequently to avoid any unwanted spread of diseases. While cleaning the waste water, built up sludge is found in pits and wells at treatment plants.

Why is aeration important?

Aeration accelerates the ability of those ecosystems to clean polluted waters. Todd’s team designs Restorers mainly for industrial applications. Tyson Foods approached Todd when its plant in Berlin, Maryland was prohibited from discharging wastewater into a local fishing site near Chesapeake Bay.

Who is John Todd?

Bob Feinbaum. JOHN Todd founded Ocean Arks International in the 1980s, where he started to experiment with processes that mimic natural ways to purify wastewater. He built a greenhouse and ran sewage through a series of tanks, with plants suspended in the flowing waters, and constructed marshes made of sand and gravel.

Who is the founder of Ocean Arks?

OCEAN ARKS INTERNATIONAL. OCEAN Arks International (OAI) was founded in 1981 by John Todd and his wife, Nancy Jack Todd, with the goal of applying ecological design principles throughout the world. The Todds first applied their approach to designing and building engineered ecosystems for growing food.

Why do large facilities use mechanically cleaned screening systems?

As discussed above, most large facilities usemechanically cleaned screening systems to removelarger materials because they reduce labor costs andthey improve flow conditions and screening capture .Typically, only older or smaller treatment facilitiesuse a manually cleaned screen as the primary oronly screening device. A screening compactor isusually situated close to the mechanically cleanedscreen and compacted screenings are conveyed to adumpster or disposal area. However, plantsutilizing mechanically cleaned screens should havea standby screen to put in operation when theprimary screening device is out of service. This isstandard design practice for most newly designedplants.

How are screening devices classified?

Screening devices are classified based on the size ofthe material they remove (the screenings). The“size” of screening material refers to its diameter.Table 2 lists the correlation between screening sizesand screening device classification.

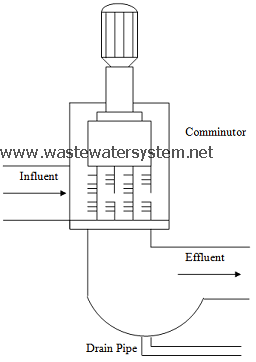

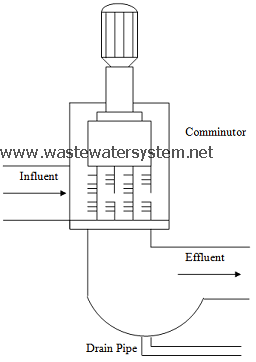

How does processing coarse solids reduce their size?

Processing coarse solids reduces their size so theycan be removed during downstream treatmentoperations, such as primary clarification, where bothfloating and settleable solids are removed.Comminut ing and grinding devices are installed inthe wastewater flow channel to grind and shredmaterial up to 6 to 19 mm (0.25 to 0.75 in) in size.