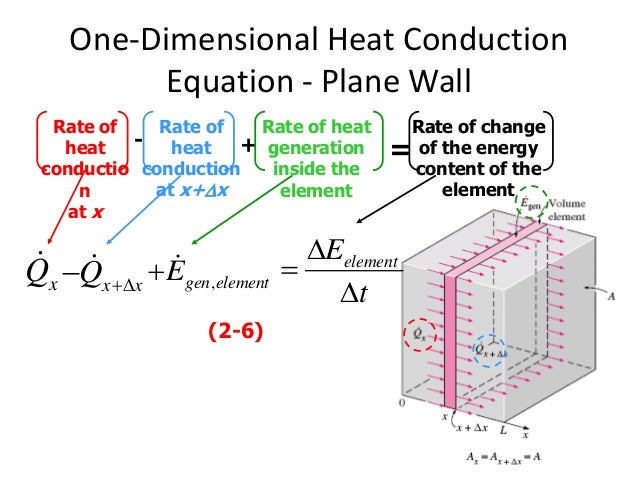

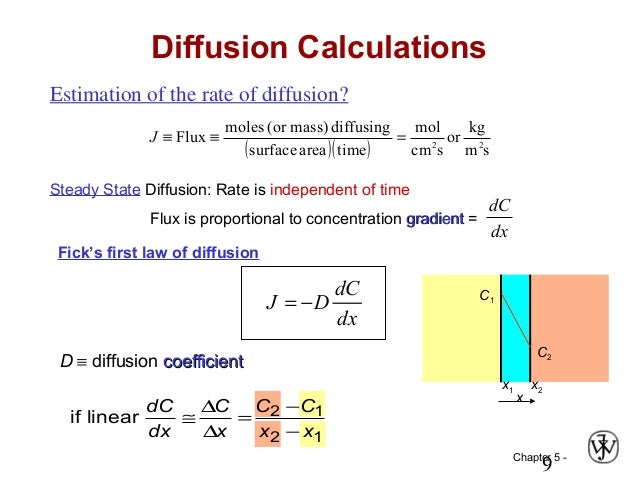

If the diffusion coefficient doesn’t depend on the density, i.e., Dis constant, thenEq. (7.1) reduces to the following linear equation: ¶u(r,t) =DÑ2u(r,t). (7.2)¶t Equation (7.2) is also calledthe heat equationand also describes the distribution ofa heat in a given region over time.

Why is the heat equation also called the diffusion equation?

For this reason, the heat equation is also called diffusion equation. For a three-dimensional case of heat conduction, heat flows no longer have to be considered in one dimensional direction only, but in all three directions (this also applies to the mass flows in the case of diffusion).

What is the diffusion equation for the three-dimensional case?

Thus, the diffusion equation for the three-dimensional case is as follows (assuming isotropic material for which k is identical in all three spatial directions): ∂u(→s, t) ∂t = k ⋅ ∂2u ∂x2 + k ⋅ ∂2u ∂y2 + k ⋅ ∂2u ∂z2 and →s = (x y z)

What determines the time required for solution heat treatment?

The product form can determine the time required for solution heat treatment. For example, castings require more time than wrought products to dissolve their relatively large constituents into solution. The time required can vary anywhere from less than a minute for thin sheet up to 20 h for large sand castings.

How does diffusion work in a carbon free furnace?

This diffusion will work only if the steel has low carbon content, because diffusion works on the differential of concentration principle. If, for example the steel had high carbon content to begin with, and is heated in a carbon free furnace, such as air, the carbon will tend to diffuse out of the steel resulting in Decarburization.

What is diffusion in heat treatment?

Diffusion hardening is a process used in manufacturing that increases the hardness of steels. In diffusion hardening, diffusion occurs between a steel with a low carbon content and a carbon-rich environment to increase the carbon content of the steel and ultimately harden the workpiece.

How do you calculate soaking time for heat treatment?

There is a range of different tempering temperatures. For 1045 steel the range is from 392 to 932°F....Table 1: Approximate Soaking Time for Hardening, Annealing and Normalizing Steel.Thickness Of Metal (inches)Time of heating to required Temperature (hr)Soaking time (hr)5 to 83.50 to 3.751 to 1.509 more rows

What are the different methods in diffusion heat treatment?

These techniques include electroplating, hard coating (thermal flame spray), physical vapor deposition (PVD) and chemical vapor deposition (CVD). Diffusion techniques are further subdivided into two distinctive categories: thermochemical and thermal.

What is the Harris equation for carburizing?

The carbon penetration rate, V, at every time, h, of the carburizing process may be calculated theoretically by the Harris formula to determine the case depth penetration as a function of time: p = 803 h1/2/103722/T; V = dp/dh = (803.1/2 h1/2 – 1)/103722/T = 401.5/ (h1/2.

What is holding time in heat treatment?

Heating time and holding time refer, respectively, to the time required to bring a part to temperature and the time a part is held at the required heat-treatment temperature.

How do you calculate Pwht holding time?

Material thickness 25m and diameter 273mm. As per EN 13480-4 it requires Pwht holding time (2xt) = 50 minutes. As per EN 15614-1, t=25mm thickness, qualification thickness range is 12.5

Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching.

Critical temperature of steel defines phase transition between two phases of steel. As the steel is heated above the critical temperature, about 1335°F (724°C), it undergoes a phase change, recrystallizing as austenite.

4 TypesWhat are the 4 Types of Heat Treating Processes? Common types of heat treating methods include annealing, hardening, quenching, and stress relieving, each of which has its own unique process to produce different results.

Carburizing, also referred to as Case Hardening, is a heat treatment process that produces a surface which is resistant to wear, while maintaining toughness and strength of the core. This treatment is applied to low carbon steel parts after machining, as well as high alloy steel bearings, gears, and other components.

The microstructure of the core won't be altered during this low temperature processing. While carburization is used mainly for low carbon steels and low alloy steels, nitriding is used for low carbon steels, alloy steels, tool steels and stainless steels. Nitrided steels can have superior wear resistance and hardness.

Carburising is a thermochemical process in which carbon is diffused into the surface of low carbon steels to increase the carbon content to sufficient levels so that the surface will respond to heat treatment and produce a hard, wear-resistant layer.

What do you mean by "carbon diffusion" ? Is it "Diffusivity and/or Diffusion Coefficient of Carbon" or "Mass Transfer Coefficient".

I do not know about dilatometry but dye penetration or ppm level of radio isotopes in carbon can give a good picture of diffusion depths, rates and coefficients. Change in electrical conductivity through probes on a machined surface can also get you a good picture.

How to write a udf to define average temperature at one boundary based on the value on another boundary?

This is done by exposing the part to a Carbon rich atmosphere at an elevated temperature and allows diffusion to transfer the Carbon atoms into steel. This diffusion will work only if the steel has low carbon content, because diffusion works on the differential of concentration principle. If, for example the steel had high carbon content ...

Pack Carburizing: Parts are packed in a high carbon medium such as carbon powder or cast iron shavings and heated in a furnace for 12 to 72 hours at 900 ºC (1652 ºF). At this temperature CO gas is produced which is a strong reducing agent.

The temperature diffusion is as good as it can be with a furnace. The only concern is to safely contain the CO gas. A variation of gas carburizing is when alcohol is dripped into the furnace and it volatilizes readily to provide the reducing reaction for the deposition of the carbon.

At the nose of the curve, M23C6 needs at least a few minutes to form. This indicates reasonable resistance to sensitization, as a weld or a solution heat treatment could be cooled fast enough to avoid M23C6 precipitation.

Carburization is a surface-hardening technique in which carbon is added to the surface of steel at temperatures generally between 850 °C and 950 °C. The case depth of carburized steel is a function of carburizing time and the available carbon potential at the surface. When prolonged carburizing times are used for deep case depths, a high carbon potential produces a high carbon content at the surface, which may result in excessive retained austenite and/or the precipitation of carbides. Both of these have adverse effects on the distribution of residual stress in the case-hardened part. Consequently, a high carbon potential may be suitable for short carburizing times, but not for prolonged carburizing.

Hi, agree with all of you. I use to manage 50mm/h or a most optimistic 1mm/min, but other interesting point here is related to the temperature achieved.

Yes there are certain thumb rules for certain classes of alloys. In case of steels the thumb rule for annaealing/ hardening would be 1 hr/ inch. For temperiing it would be 2 Hr/Inch.

It is very important manufacturing process that can not only help the manufacturing process but can also improve the product, its performance, and its characteristics in many ways. By Heat Treatment process, Example: The plain carbon steel. The following changes may be achieved: The hardness of Steel may be increased or decreased.

Annealing consists of heating of steel parts to a temperature at or near the critical temperature 900 degree Celsius hold it at that temperature for a suitable time and when allowed to cool slowly in the Furnace itself. The heating done during annealing affects the metal in two stages of recovery and recrystallization.

Normalizing carried for accomplishing one or more of the following: To refine the grain size. Reduce or remove internal stresses. Improve the machinability of low carbon steel. Increase the strength of medium carbon steel. And also To improve the mechanical properties of the medium Carbon Steel.

Normalizing is a heat treatment process similar to annealing in which the Steel is heated to about 50 degree Celsius above the upper critical temperature followed by air cooling. This results in a softer state which will be lesser soft than that produced by annealing.

During this process, when Ammonia comes in contact with steel is diffuses into nascent hydrogen and nascent nitrogen. This nascent nitrogen so produced diffuses into the surface of the workpiece forming hard nitrites which increase surface hardness.

What are the five basic heat treatment process?

What is critical temperature in heat treatment?

How many types of heat treatment are there?

Is carburizing the same as case hardening?

What steels can be Carburized?

What is the carburizing process?

Most recent answer

All Answers (5)

Similar questions and discussions

How does diffusion work?

How long does it take to heat a pack carburizing?

Is temperature diffusion good?

How long does it take for M23C6 to form?

What temperature is carburized steel?

Most recent answer

All Answers (15)

Why is heat treatment important?

What temperature does annealing take place?

What is normalizing carried for accomplishing?

What is normalizing steel?

What happens when ammonia is in contact with steel?

Popular Posts: