Solution treating usually is done in molten salt, but may be done in a controlled-atmosphere furnace to prevent surface scaling and internal oxidation. Solution treated chromium copper is aged at 400 to 500 o C for several hours to produce the desired mechanical and physical properties. A typical aging cycle is 455 o C for 4 h or more.

What is solution heat treatment?

What is solution heat treatment? Solution Heat Treatment is a treatment in which an aluminum alloy is heated to a suitable temperature and held at this temperature for a sufficient length of time to allow the desired constituent to enter into the solid solution, followed by rapid cooling to hold the constituent in the solution. .

What is the correct holding time for heat treatment?

ASM handbook volume 4 gives holding time for different heat treatment and different materials. Usual thumb rule is 1hr/inch of radius for cylindrical bars and for big blocks it is 1h/inch of thickness. Bohler handbook also give you the details about soaking.

How long does it take to heat treat steel?

Plain carbon and low-alloy steel with easily dissolved carbides only require a few minutes holding time after reaching the austenitizing temperature, and a holding time of 5 to 15 minutes is usually sufficient. For medium-alloy structural steels a holding time of 15 to 20 minutes is suggested. The AMS2750E is a standard for the heat treatment.

How does heat treating work?

This guide to heat treating would not be complete without the actual types of heat treating: In this process, the metal is heated to a temperature which causes the elements in the metal to switch to being a solution. Prior to these defects in the crystal lattice structure of the metal are the main source of plasticity.

What is heat treating?

How does heat treat metal?

What is the process of annealing?

How does heat treatment affect metal?

Why is steel treated with air cooled?

Does case hardening make metals brittle?

See more

What is the process of solution heat treatment?

Solution treatment is a heat treating process that heats alloys to a specific temperature, sustaining that temperature long enough to cause one or more constituents to enter into a solid solution and then rapidly cooled to maintain the solution's properties.

What is soaking time in heat treatment?

Soak time is the amount of time the steel is held at the desired temperature, which is in this case 1500 degrees Fahrenheit. 5. When the soak time is complete, very quickly but carefully take the sample out with tongs. Place the sample part into a tank of oil for quenching.

How do you determine holding time for heat treatment?

Plain carbon and low-alloy steel with easily dissolved carbides only require a few minutes holding time after reaching the austenitizing temperature, and a holding time of 5 to 15 minutes is usually sufficient. For medium-alloy structural steels a holding time of 15 to 20 minutes is suggested.

What is the difference between solution and precipitation heat treatment?

Solid solution strengthening involves formation of a single-phase solid solution via quenching. Precipitation heat treating involves the addition of impurity particles to increase a material's strength.

What is the soak time?

Soak Time means the period of time beginning when the pot is dropped overboard and ending when it is lifted above the surface of the water. Soak Time means the number of days from the date a pot is set in the water until the date it is next hauled.

What is soaking time why it is necessary?

The purpose of the soaking stage is to keep the metal at the appropriate temperature until the desired internal structure takes shape. The “soaking period” is how long you keep the metal at the appropriate temperature. To determine the correct length of time, you will need the chemical analysis and mass of the metal.

What are the 3 stages of heat treatment process?

The stages of the heat treatment process include heating, soaking, and cooling.Heating: Heating is the first stage in a heat-treating process. ... Soaking: Soaking is the stage at which the complete part of the heated metal completely changes in its structure. ... Cooling: The third stage of heat treatment is cooling.

What are the five basic heat treatment process?

Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching.

How long does it take to heat steel?

in diameter, the heating time per inch of section thickness should be no more than 5 minutes for low-carbon and mediumcarbon steels, or more than 6 minutes for low-alloy steels. For stock 3 to 9 in.

What are the three steps in age hardening?

Precipitation hardening takes place in three steps:Solution annealing. The first step of precipitation hardening is called “solution annealing”. ... Quenching. Once the alloying materials are dissolved into the surface of the part, rapid cooling takes place until the solubility limit is exceeded. ... Aging.

What is solid solution treatment?

Solid solution strengthening is a type of alloying that can be used to improve the strength of a pure metal. The technique works by adding atoms of one element (the alloying element) to the crystalline lattice of another element (the base metal), forming a solid solution.

What is solution treatment of steel?

Solution Treatment is the common heat treatment method for stainless steel castings. Solution treatment refers to the heat treatment process that heating stainless steel castings to a high temperature and keeping constant temperature, so that the excess phase is fully dissolved into the solid solution.

Rapid cooling for strong results

Solution treatment is a heat treating process that heats alloys to a specific temperature, sustaining that temperature long enough to cause one or more constituents to enter into a solid solution and then rapidly cooled to maintain the solution’s properties.

Find the Right Solution

We’re ready to help you find the right solution treatment for your project. Contact us today to request a quote or learn more.

What is heat treating?

Heat treating is a pre and post-manufacturing process which is used to change a number of properties of metals and their alloys. The primary use of heat treating is to make the metal suitable for a particular application.

How does heat treat metal?

Prior to these defects in the crystal lattice structure of the metal are the main source of plasticity. The heat-treating process addresses these deficiencies in the steel by making the metal into a reliable solution with fine particles to strengthen the metal. Once this phase is achieved the solution is rapidly quenched to trap the particles in the solution.

What is the process of annealing?

Anealing. In the annealing process, various metals such as aluminum, steel, copper, brass or silver are heated to a set temperature and held there for a certain amount of time so that a transformation occurs, it is then air-cooled.

How does heat treatment affect metal?

Heat treating can affect a number of different aspects of the metal including strength, hardness, toughness, machinability, formability, ductility, and elasticity. It can also affect the physical and mechanical properties of metal to change the use of the metal or alter future work on the metal.

Why is steel treated with air cooled?

The heat-treating creates small austenitic grains whilst the air cooling produces more refined ferritic grains. The normalization process improves the strength, machinability, and durability of the steel.

Does case hardening make metals brittle?

The process itself used high heat in combination with various elements and chemicals to achieve the hardened layer. Typical hardening can make metals more brittle, that is when case hardening comes into its own when an application requires a flexible inner layer with a durable outer layer.

How long does it take to soak steel?

This is just for a guide. Diameter is 1 inch- 45 minutes- soaking time 30 minute. Diameter 1-2 inch- 75 minutes- soaking time 30 minute. Diameter 2-3 inch- 105 minute-soaking times 45 minute.

How long to hold carbon steel?

Plain carbon and low-alloy steel with easily dissolved carbides only require a few minutes holding time after reaching the austenitizing temperature, and a holding time of 5 to 15 minutes is usually sufficient. For medium-alloy structural steels a holding time of 15 to 20 minutes is suggested.

Why is soaking a part of the furnace?

Soaking is actually holding time of particular thing at constant temperature so that there is uniform distribution of heat throughout the material. A uniform temperature distribution is obtained by soaking a particular thing ...

Why is heat treatment important?

It is very important manufacturing process that can not only help the manufacturing process but can also improve the product, its performance, and its characteristics in many ways. By Heat Treatment process, Example: The plain carbon steel. The following changes may be achieved: The hardness of Steel may be increased or decreased.

What temperature does annealing take place?

Annealing consists of heating of steel parts to a temperature at or near the critical temperature 900 degree Celsius hold it at that temperature for a suitable time and when allowed to cool slowly in the Furnace itself. The heating done during annealing affects the metal in two stages of recovery and recrystallization.

How to cool down after heatstroke?

To cool your body to a normal temperature, your doctor may use these heatstroke treatment techniques: 1 Immerse you in cold water. A bath of cold or ice water has been proved to be the most effective way of quickly lowering your core body temperature. The quicker you can receive cold water immersion, the less risk of death and organ damage. 2 Use evaporation cooling techniques. If your core body temperature is not in the heatstroke range and if cold water immersion is not available, health care workers may try to lower your body temperature using an evaporation method. Cool water is misted on your body while warm air is fanned over you, causing the water to evaporate and cool your skin. 3 Pack you with ice and cooling blankets. Another method is to wrap you in a special cooling blanket and apply ice packs to your groin, neck, back and armpits to lower your temperature. 4 Give you medications to stop your shivering. If treatments to lower your body temperature make you shiver, your doctor may give you a muscle relaxant, such as a benzodiazepine. Shivering increases your body temperature, making treatment less effective.

How to bring down temperature?

If possible, take a cool shower, soak in a cool bath, or put towels soaked in cool water on your skin . If you're outdoors and not near shelter, soaking in a cool pond or stream can help bring your temperature down. Loosen clothing. Remove any unnecessary clothing and make sure your clothes are lightweight and nonbinding.

What tests are needed for heatstroke?

If your doctors suspect your heat exhaustion may have progressed to heatstroke, you may need additional tests, including: A blood test to check for low blood sodium or potassium and the content of gases in your blood. A urine test to check the concentration and composition of your urine and to check your kidney function, ...

What is the best treatment for shivering?

If treatments to lower your body temperature make you shiver, your doctor may give you a muscle relaxant, such as a benzodiazepine. Shivering increases your body temperature, making treatment less effective. By Mayo Clinic Staff.

How to get water to evaporate?

Cool water is misted on your body while warm air is fanned over you, causing the water to evaporate and cool your skin. Pack you with ice and cooling blankets. Another method is to wrap you in a special cooling blanket and apply ice packs to your groin, neck, back and armpits to lower your temperature.

Can heat exhaustion be diagnosed?

Diagnosis. If you need medical attention due to heat exhaustion, it may be apparent to medical personnel that you have heat exhaustion, or they may take your rectal temperature to confirm the diagnosis and rule out heatstroke.

Why is heat treatment called an arrest?

This temperature is referred to as an "arrest" because at the A temperature the metal experiences a period of hysteresis.

What is the process of heating something to alter it?

Process of heating something to alter it. Heat treating furnace at 1,800 °F (980 °C) Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the ...

What happens when an alloy is cooled to an insoluble state?

If the alloy is cooled to an insoluble state, the atoms of the dissolved constituents (solutes) may migrate out of the solution. This type of diffusion, called precipitation, leads to nucleation, where the migrating atoms group together at the grain-boundaries.

What is a semi continuous batch furnace?

These upgraded furnaces are a very commonly used piece of equipment for heat-treating.

Does cooling a metal cause precipitation?

Cooling a metal will usually suppress the precipitation to a much lower temperature. Austenite, for example, usually only exists above the upper critical temperature. However, if the austenite is cooled quickly enough, the transformation may be suppressed for hundreds of degrees below the lower critical temperature.

What is heat treating?

Heat treating is a pre and post-manufacturing process which is used to change a number of properties of metals and their alloys. The primary use of heat treating is to make the metal suitable for a particular application.

How does heat treat metal?

Prior to these defects in the crystal lattice structure of the metal are the main source of plasticity. The heat-treating process addresses these deficiencies in the steel by making the metal into a reliable solution with fine particles to strengthen the metal. Once this phase is achieved the solution is rapidly quenched to trap the particles in the solution.

What is the process of annealing?

Anealing. In the annealing process, various metals such as aluminum, steel, copper, brass or silver are heated to a set temperature and held there for a certain amount of time so that a transformation occurs, it is then air-cooled.

How does heat treatment affect metal?

Heat treating can affect a number of different aspects of the metal including strength, hardness, toughness, machinability, formability, ductility, and elasticity. It can also affect the physical and mechanical properties of metal to change the use of the metal or alter future work on the metal.

Why is steel treated with air cooled?

The heat-treating creates small austenitic grains whilst the air cooling produces more refined ferritic grains. The normalization process improves the strength, machinability, and durability of the steel.

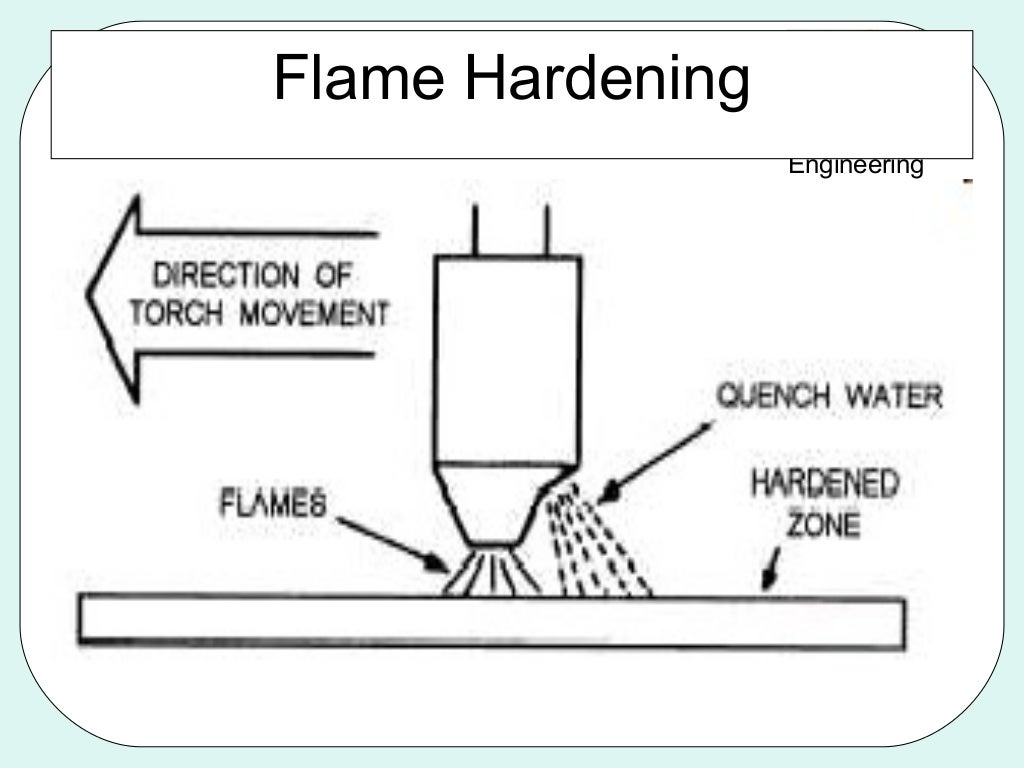

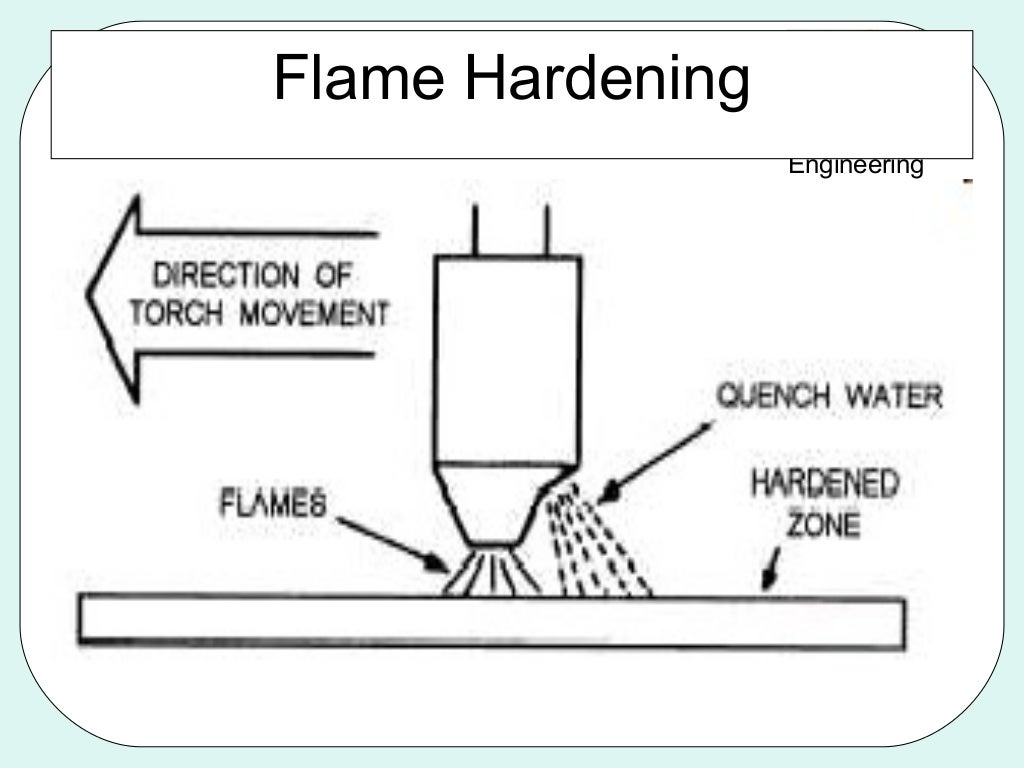

Does case hardening make metals brittle?

The process itself used high heat in combination with various elements and chemicals to achieve the hardened layer. Typical hardening can make metals more brittle, that is when case hardening comes into its own when an application requires a flexible inner layer with a durable outer layer.

Overview

Techniques

Complex heat treating schedules, or "cycles", are often devised by metallurgists to optimize an alloy's mechanical properties. In the aerospace industry, a superalloy may undergo five or more different heat treating operations to develop the desired properties. This can lead to quality problems depending on the accuracy of the furnace's temperature controls and timer. These operation…

Physical processes

Metallic materials consist of a microstructure of small crystals called "grains" or crystallites. The nature of the grains (i.e. grain size and composition) is one of the most effective factors that can determine the overall mechanical behavior of the metal. Heat treatment provides an efficient way to manipulate the properties of the metal by controlling the rate of diffusion and the rate of cooling within th…

Effects of composition

The specific composition of an alloy system will usually have a great effect on the results of heat treating. If the percentage of each constituent is just right, the alloy will form a single, continuous microstructure upon cooling. Such a mixture is said to be eutectoid. However, If the percentage of the solutes varies from the eutectoid mixture, two or more different microstructures will usually form sim…

Effects of time and temperature

Proper heat treating requires precise control over temperature, time held at a certain temperature and cooling rate.

With the exception of stress-relieving, tempering, and aging, most heat treatments begin by heating an alloy beyond a certain transformation, or arrest (A), temperature. This temperature is referred to as an "arrest" because at the A temperature the metal experiences a period of hystere…

Specification of heat treatment

Usually the end condition is specified instead of the process used in heat treatment.

Case hardening is specified by hardness and case depth. The case depth can be specified in two ways: total case depth or effective case depth. The total case depth is the true depth of the case. For most alloys, the effective case depth i…

Furnace types

Furnaces used for heat treatment can be split into two broad categories: batch furnaces and continuous furnaces. Batch furnaces are usually manually loaded and unloaded, whereas continuous furnaces have an automatic conveying system to provide a constant load into the furnace chamber.

Batch systems usually consist of an insulated chamber with a steel shell, a hea…

See also

• Carbon steel

• Carbonizing

• Diffusion hardening

• Induction hardening

• Retrogression heat treatment