How does a surface water treatment plant work?

Water is passed through a filter made of sand, coal particles or similar materials that removes particles such as silt, other very fine solids, and some pathogens not settled in the sedimentation process. Filtration further reduces turbidity and results in water that is crystal clear.

What are the steps of a water treatment plant?

They typically consist of several steps in the treatment process. These include: (1) Collection ; (2) Screening and Straining ; (3) Chemical Addition ; (4) Coagulation and Flocculation ; (5) Sedimentation and Clarification ; (6) Filtration ; (7) Disinfection ; (8) Storage ; (9) and finally Distribution.

What are the methods used in surface water treatment?

Two processes are commonly used to treat surface water: - Conventional treatment including clarification (coagulation/flocculation, sedimentation or dissolved air flotation), sand filtration, activated carbon adsorption and disinfection. - Advanced treatment based on ultrafiltration technology.

What are the four steps in treating surface water?

Introduce the steps in the water-treatment process. The correct order is: coagulation, sedimentation, filtration, and disinfection.Nov 25, 2021

What are the 5 steps of water treatment?

The 5 major unit processes include chemical coagulation, flocculation, sedimentation, filtration, and disinfection (described below). There are chemicals added to the water as it enters the various treatment processes.

What are the 3 stages of water treatment?

There are three main stages of the wastewater treatment process, aptly known as primary, secondary and tertiary water treatment. In some applications, more advanced treatment is required, known as quaternary water treatment.Dec 6, 2018

What are the 7 methods of water treatment?

Top 7 Methods of Water TreatmentCoagulation / Flocculation. Coagulation is adding liquid aluminum sulfate or alum and/or polymer to raw or untreated water. ... Sedimentation. When water and flocs undergo the treatment process, they go into sedimentation basins. ... Filtration. ... Disinfection. ... Sludge Drying. ... Fluoridation. ... pH Correction.Nov 7, 2015

What are the major steps of drinking water treatment using surface water as the source list them in the order of treatment process?

1:234:19Water and You: The Water Treatment Process - YouTubeYouTubeStart of suggested clipEnd of suggested clipThey do such a good job that American water often provides water service that is better than whatMoreThey do such a good job that American water often provides water service that is better than what the government requires the treatment process begins. Here at the pumping station pumps draw raw water

What is aeration in water treatment?

Aeration treatment consists of passing large amounts of air through water and then venting the air outside. The air causes the dissolved gases or volatile compounds to release from the water.Aug 23, 2019

How does surface water treatment work?

In order to meet the requirements of the Surface Water Treatment Rule, a water system must both remove and inactivate the pathogens in the water. This process begins with coagulation, which destabilizes the particles in the water. Then, during flocculation, the destabilized particles bump into each other and form larger and larger flocs. These large flocs are given adequate time to settle out of solution via gravity during sedimentation. Any remaining particles and pathogens will be removed during the filtration treatment process. Finally, the water is disinfected to inactivate any remaining pathogens prior to entering the water system’s distribution system.

What is the purpose of the Surface Water Treatment Rule?

The goal of the SWTR is to reduce illnesses related to pathogens in drinking water. These pathogens include coliform, Giardia, and Cryptosporidium .

How do clarifiers work?

The large flocs will settle out of suspension via gravity. Clarifiers can remove a very large percentage of the suspended materials in water. In some plants, clarifiers remove as much as 90% of the suspended solids load. Particles that do not settle will be removed by filtration in the next treatment step.

What is coagulation in water treatment?

History of Coagulation in Drinking Water Treatment. Coagulation has been an important process in high-rate filtration plants in the United States since the 1880s. Aluminum and iron salts have been used in the coagulation process since the beginning. These salts are still the most commonly used coagulants today.

What is turbidity in water?

This cloudiness is known as turbidity . Visual turbidity is unpleasant to consumers. Visual turbidity is also an indicator to operators and regulators that the water may still contain pathogens. The Surface Water Treatment Rule therefore requires that turbidity be removed to very low levels.

What is the process of increasing the tendency of small particles to attach to one another and to attach to surfaces such as the

Coagulation . Coagulation is defined as the water treatment process of increasing the tendency of small particles to attach to one another and to attach to surfaces such as the grains of a filter bed. Many surface water supplies contain particles that are too small to settle out of solution on their own.

How does contact time work in water treatment?

In order for systems to be sure that they are properly disinfecting the filtered water, the Surface Water Treatment Rule requires systems to provide enough contact time. Contact time (CT) is a function of the known disinfection concentration and the amount of time that the disinfectant is in contact with the water. Contact time is expressed in terms of mg/L-min. The EPA has published tables that show how much CT credit water systems will receive. In order to use these tables you use the concentration of chlorine, time, water temperature and pH.

What is the first step in surface water treatment?

When water enters a treatment plant [see also Water Treatment ], the first step is coagulation, the rapid mixing of coagulants such as aluminum sulfate, ferric chloride and organic polymers into the water.

What is the purpose of adding disinfectant to water?

During the treatment process, an effort is made to add enough disinfectant to leave a residual amount in the water to continue to kill any pathogens in the pipelines that convey the water to users.

Why is aeration used in water?

Aeration, the mixture of air with water, sometimes is used if undesirable amounts of iron and manganese are present; the elements remain in solution in water in the absence of oxygen. Aeration is done primarily to improve the aesthetics of water: color, taste and odor.

What is the next step in flocculation?

The next step is flocculation: water is gently agitated so the flocs or particles will collide with each other, stick together and entrap other suspended particles, forming larger, heavier particles that will settle out in the next step.

How many connections does California have to fluoridate water?

California law requires fluoridation of water in systems with 10,000 or more connections. State officials say 30 percent of all public water providers in California fluoridate their water. Other chemicals may be added to water during the course of treatment for specific purposes.

What is water filter made of?

Water is passed through a filter made of sand, coal particles or similar materials that removes particles such as silt, other very fine solids, and some pathogens not settled in the sedimentation process . Filtration further reduces turbidity and results in water that is crystal clear.

What is the purpose of filtration?

Filtration further reduces turbidity and results in water that is crystal clear. Activated carbon also may be used to remove chemical contaminants. Rather than being trapped in the small passageways between grains of sand, contaminants stick to the surface of carbon and are removed, a process known as carbon adsorption.

What is the Cajon City water treatment plant?

The Cañon City Water Treatment Plant is a conventional surface water treatment plant that diverts water from the Arkansas River to produce drinkable (potable) water, which meets or exceeds all Environmental Protection Agency ( EPA) Safe Drinking Water Act and the Colorado Department of Public Health and Environment Primary Drinking Water Standards.

How is potable water run?

Potable water is run backwards through the filters releasing the entrapped particulates that are collected in drain troughs. The backwash water is sent to the Backwash Recovery Pond and, after a settling process, the backwash water is returned to the raw water settling pond for re-use.

What is the process of flocculation?

The flocculation process promotes contact between the floc particles and the particulates (sediment) in the water. Generally, these contacts or collisions between particles result from gentle stirring created by a mechanical or hydraulic means of mixing.

How does sedimentation work?

Sedimentation is accomplished by decreasing the velocity of the water being treated below the point where it can transport settleable suspended material, thus allowing gravitational forces to remove particles held in suspension. When water is almost still in sedimentation basins, settleable solids will move toward the bottom of the basin. This process of sedimentation removes almost ninety percent of the solids in the water. The clearer water on the surface is collected in the launder tubes that direct the water to the filter gallery to remove the remaining ten percent of solids.

How does the pre sedimentation process work?

The raw water is delivered to the headworks of the water treatment plant where the first of 5 major unit water treatment processes start the treatment to make the water safe to drink. The 5 major unit processes include chemical coagulation, flocculation, sedimentation, filtration, and disinfection (described below). There are chemicals added to the water as it enters the various treatment processes.

What is the first chemical added to water?

The first chemical added is chlorine dioxide and it is an oxidant used to break down naturally occurring organic matter such as decaying leaves and other plant material. A chemical coagulant known as aluminum sulfate is used as the primary coagulant. A polymer, a long chain of synthetic organic compounds, is also added to the water as a coagulant aid to help in strengthening the primary coagulant’s bonding chains. The coagulants are added at the rapid mix unit; this is a unit that creates turbulent mixing energies to help thoroughly disperse the chemical coagulants into the raw water and to begin the coagulation process. The coagulants that cause very fine particles to clump together into larger particles that can then be removed later in the treatment process by settling, skimming, draining or filtering.

What is a PLC in water treatment?

Devices known as programmable logic controllers ( PLCs) that are networked together with other PLCs control the water treatment plant and the treatment processes. The PLCs track over 1,500 signals or data points to ensure optimized treatment. The computer signals and data are collected by the Supervisory Collection and Data Acquisition ( SCADA) system and provide information to the Operator on shift whenever any item requires Operator intervention.

1. Pre-treatment Phase

The pre-treatment phase that occurs at a wastewater treatment plant is designed to get rid of the larger and easier to remove items from the water. These items can include everything from tree branches and cans to plastic bottles and rags.

2. Primary Treatment Phase

Once the pre-treatment phase concludes, the primary treatment phase can begin. The wastewater will be collected in sedimentation tanks and large basins at this point, which is done to allow contaminants to sink to the bottom of the water.

3. Secondary Treatment Phase

This is a very important phase of the wastewater treatment process that involves the agitation and aeration of the water within secondary basins. It’s at this point in the process that microorganisms are added to the water in order to break down any organic matter into sludge that can be more readily discarded.

4. Sludge Treatment Phase

The final phase of the wastewater treatment process is referred to as the sludge treatment phase. During the secondary treatment phase, the solids and organic matter that remain in the water are converted into sludge that can be treated and recycled.

How does a water treatment unit work?

Even though EPA regulates and sets standards for public drinking water, many Americans use a home water treatment unit to: 1 Remove specific contaminants 2 Take extra precautions because a household member has a compromised immune system 3 Improve the taste of drinking water

What are the steps of water treatment?

Today, the most common steps in water treatment used by community water systems (mainly surface water treatment) include: Coagulation and flocculation are often the first steps in water treatment. Chemicals with a positive charge are added to the water.

What is the process of boiled water?

Distillation is a process in which impure water is boiled and the steam is collected and condensed in a separate container, leaving many of the solid contaminants behind. Disinfection. Disinfection is a physical or chemical process in which pathogenic microorganisms are deactivated or killed.

Why is surface water more contaminated than ground water?

Typically, surface water requires more treatment and filtration than ground water because lakes, rivers, and streams contain more sediment and pollutants and are more likely to be contaminated than ground water. Some water supplies may also contain disinfections by-products, inorganic chemicals, organic chemicals, and radionuclides.

What is a water softener?

Water Softeners. A water softener is a device that reduces the hardness of the water. A water softener typically uses sodium or potassium ions to replace calcium and magnesium ions, the ions that create “hardness.”. Distillation Systems.

What is the most common type of water treatment system?

The most common types of household water treatment systems consist of: Filtration Systems. A water filter is a device which removes impurities from water by means of a physical barrier, chemical, and/or biological process. Water Softeners. A water softener is a device that reduces the hardness of the water.

Why do people use water treatment units?

Even though EPA regulates and sets standards for public drinking water, many Americans use a home water treatment unit to: Remove specific contaminants. Take extra precautions because a household member has a compromised immune system. Improve the taste of drinking water.

What is water treatment?

Water treatment is any process that improves the quality of water to make it appropriate for a specific end-use. The end use may be drinking, industrial water supply, irrigation, river flow maintenance, water recreation or many other uses, including being safely returned to the environment. Water treatment removes contaminants ...

Why use multiple barrier approach in surface water treatment plant?

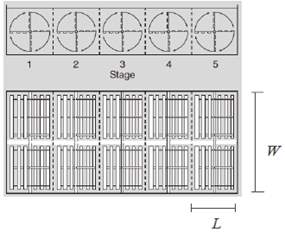

In a surface water treatment plant units used are: A multiple barrier approach should be adopted for reliability reasons of safety in the water supply system. In the case of malefaction or maintenance of one unit, the system will be able to continue to operate with the rest of the units being in operation.

What is a water filtration unit?

A filtration unit is built-in into one of the last stages of the water treatment cycle. Filter units aim to remove the suspended solids that were not removed in the previous treatment process. The filters are made out of fine and coarse sand layers were by means of mechanical screening trapping of solid particles in between the grains of sand occur hence purifying and cleaning the water from impurities. Tests of filter performance can be done by assessing the turbidity of a sample of the water.

What is flocculation tank?

Flocculation is the slow mixing process by which fine particulates are caused to clump together into a floc. The floc may then float to the top of the liquid. The design criteria of the flocculation tank are based on previous studies assumed as common practice in the industry.

What is the process of adding chemicals to the water that promotes the clumping of fines found in the

1. COAGULATION. Coagulation is the rapid mixing process of adding compound chemicals to the water that promote the clumping of fines found in the lake (e.g. soil particles) into large flocs thus they can be easily separated. Adding of coagulants such as aluminium sulphate ( alum ), ferric sulphate or sodium aluminate will destabilise colloidal ...

How does sedimentation work?

Sedimentation is the process of removing solid particles by gravity. As per Britannica, a sedimentation tank allows suspended particles present in the water to settle out of the water as the flow rate through the tank is slow. This process allows a layer of sludge, which is a mass of solid particles coming together to form at the bottom of the tank where it can be removed. Assumptions are used to determine dimensions of the tank based on the retention time (RT) and surface overflow rate (SOR). The calculations are done as follow:

Why is water treatment important?

Water treatment removes contaminants and undesirable components or reduces their concentration so that the water becomes fit for its desired end-use. This treatment is crucial to human health and allows humans to benefit from both drinking and irrigation use.

How to operate a water treatment plant?

Water treatment plant operators typically do the following: 1 Add chemicals, such as ammonia, chlorine, or lime, to disinfect water or other liquids 2 Inspect equipment on a regular basis 3 Monitor operating conditions, meters, and gauges 4 Collect and test water and sewage samples 5 Record meter and gauge readings, and operational data 6 Operate equipment to purify and clarify water, or to process or dispose of sewage 7 Clean and maintain equipment, tanks, filter beds, and other work areas 8 Stay current on environmental laws and regulations 9 Ensure safety standards are met

What do water treatment plants use?

Water treatment plant operators typically do the following: Add chemicals, such as ammonia, chlorine, or lime, to disinfect water or other liquids. Inspect equipment on a regular basis. Monitor operating conditions, meters, and gauges. Collect and test water and sewage samples.

What is wastewater operator?

Operators are trained in emergency management procedures and use safety equipment to protect their health, as well as that of the public. Wastewater treatment plant and system operators do similar work to remove pollutants from domestic and industrial waste. Used water, also known as wastewater, travels through sewage pipes to treatment plants ...

What causes large amounts of storm water to flow into sewers?

For example, weather conditions may cause large amounts of storm water or wastewater to flow into sewers, exceeding a plant’s capacity. Emergencies also may be caused by malfunctions within a plant, such as chemical leaks or oxygen deficiencies.

What do sewage workers do?

Many others work for water, sewage, and other systems utilities and for waste treatment and disposal services. They work both indoors and outdoors. They may be exposed to noise from machinery and are often exposed to unpleasant odours.

Where does used water go?

Used water, also known as wastewater, travels through sewage pipes to treatment plants where it is treated and either returned to streams, rivers, and oceans, or used for irrigation. Are you suited to be a water treatment plant operator? Water treatment plant operators have distinct personalities. They tend to be realistic individuals, which means ...

How many hours a day do plant operators work?

Plants operate 24 hours a day, seven days a week. In small plants, operators are likely to work during the day and be on call nights and weekends. In medium and large sized plants that require constant monitoring, operators work in shifts to control the plant at all hours.

Following The Rules of SWTP Operation

- Publications and Guidance about Surface Water Treatment Plants Guidance for all aspects of your surface water treatment plant from design and construction to day-to-day operation. How to Find a Licensed Water Operator How to use our database to find out whether an operator's certification is up to date, including current continuing education credits. How to Find a Water O…

Treating Water by Designed Disinfection

- CT Study Information A Concentration-Time (CT) study is a formal determination of the disinfectant concentrations and the effective contact time provided by a water treatment plant. A CT study is required for each SWTP of each public water system. Find the information you need to prepare and submit a CT study. Controlling Nitrification in Systems with Chloramines How a pub…

Monitoring and Reporting

- Monitoring and Reporting for Surface Water Systems You must monitor your surface water system to ensure safe drinking water is provided. You must report the progress of the water treatment by your surface water treatment plant (SWTP) operations using public notifications, monitoring plans, and SWTP forms. Lab Approval Form and Instructions Public w...

Coagulation

Flocculation

Sedimentation

Filtration

Disinfection

Chlorination Operations

Conclusion

- In order to meet the requirements of the Surface Water Treatment Rule, a water system must both remove and inactivate the pathogens in the water. This process begins with coagulation, which destabilizes the particles in the water. Then, during flocculation, the destabilized particles bump into each other and form larger and larger flocs. These larg...

Pre-Treatment Phase

Primary Treatment Phase

- http://www.instagram.com/p/B-WWIQHlkY8/ Once the pre-treatment phase concludes, the primary treatment phase can begin. The wastewater will be collected in sedimentation tanks and large basins at this point, which is done to allow contaminants to sink to the bottom of the water. Once the smaller particles in the water have settled, scrapers are used...

Secondary Treatment Phase

Sludge Treatment Phase